Case List

Case List

Movable monitoring system to connect by piping

This system monitors piping connections by using IC tag readers and IC tags to visualize movable piping connections in a factory.

Baggage image traceability system

It is baggage information and soaked in string, the system which I can trace with the image which I photographed with a camera, a scanner installed on the automatic assortment line.

Jig and tool verification system

This system prevents jigs and tools from being installed incorrectly and allows users to view usage histories.

Plant control system

Plant control system (I automatically control temperature/pressure/flow quantity/levels) using the MELSEC iQ-R series process CPU

Manufacturing Information Visualization System

Equipment operation signals, sensor measurements, fault signals, etc. are imported to the SCADA server from PLCs at the manufacturing site.

Production status management system

Information such as daily production numbers and personnel man-hours is entered into a server PC.

Automated conveyor systems

The destination instruction panel sets the transfer route and route order between each process.

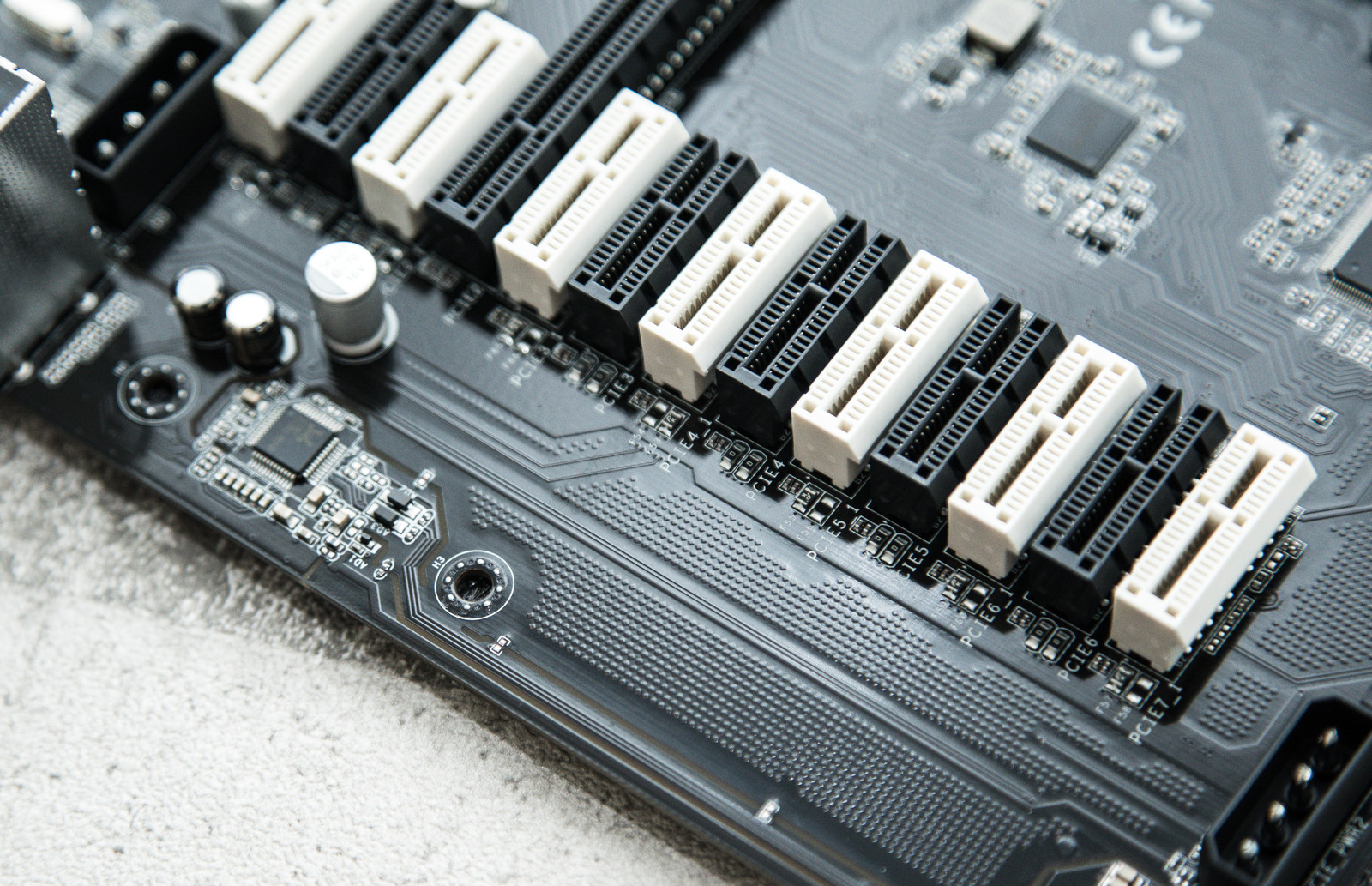

Expansion of MC protocol-compliant devices to SNAP PAC System

Control system using OPTO22 SNAP PAC System. (Automatic control of air conditioning, metering, temperature, pressure, flow rate, etc.)

AGV auxiliary elevator relay system

This system relays control communication between the existing auxiliary elevator and the new AGV transport system when a new AGV package is introduced to an old AGV transport system.

Attendance management system by IC card

By touching the IC card to the card reader when arriving at or leaving the office, you can manage the attendance status (attendance/leaving).

Power plant remote monitoring system

The system consolidates various sensor and process information for main, generator, and auxiliary equipment in a power plant, and centralizes monitoring of condition in operations.

Defective product elimination system

Defective food materials flowing on the conveyor line are judged by image processing and eliminated by the elimination robot installed in the downstream section.

Entry/exit system

Records of visitors to business sites (including factories) are digitized with a tablet-based entry/exit registration function to standardize business processes and control whether visitor behavior is in accordance with rules.

Food material cultivation control system

This is a control system that inputs raw materials and nutrients in the raw material process (upstream) of food production and cultivates highly concentrated secondary raw materials.

Picking system

The system obtains a list of refrigerated products for delivery on the same day and picking instructions from the host system, lights the indicator according to the instructions, and sends the results of the picking to the host system. (Controlled by PC)

Food production management system

The system that receives the production instruction data from the upper core server via FTP communication and registers it in the DB as the production data of the day.

Factory environment collection and monitoring system

The system periodically collects environmental information such as temperature and humidity from devices and sensors installed at multiple locations in the factory and displays it on the web.

Production instruction system

This system transfers production instruction information to the PLC on the line based on the information received from ERP/MES.

Distant power monitoring system

The system that collects information on power, power volume, power factor, etc., used in buildings from power meters installed on site using PLC.

Traceability system

It imports and saves "various tag label information," "completion date and time," "production process information," etc. from each connected process PLC.

Automatic sorting system

The control PLC automatically controls the start/stop and speed of the transport sorter.

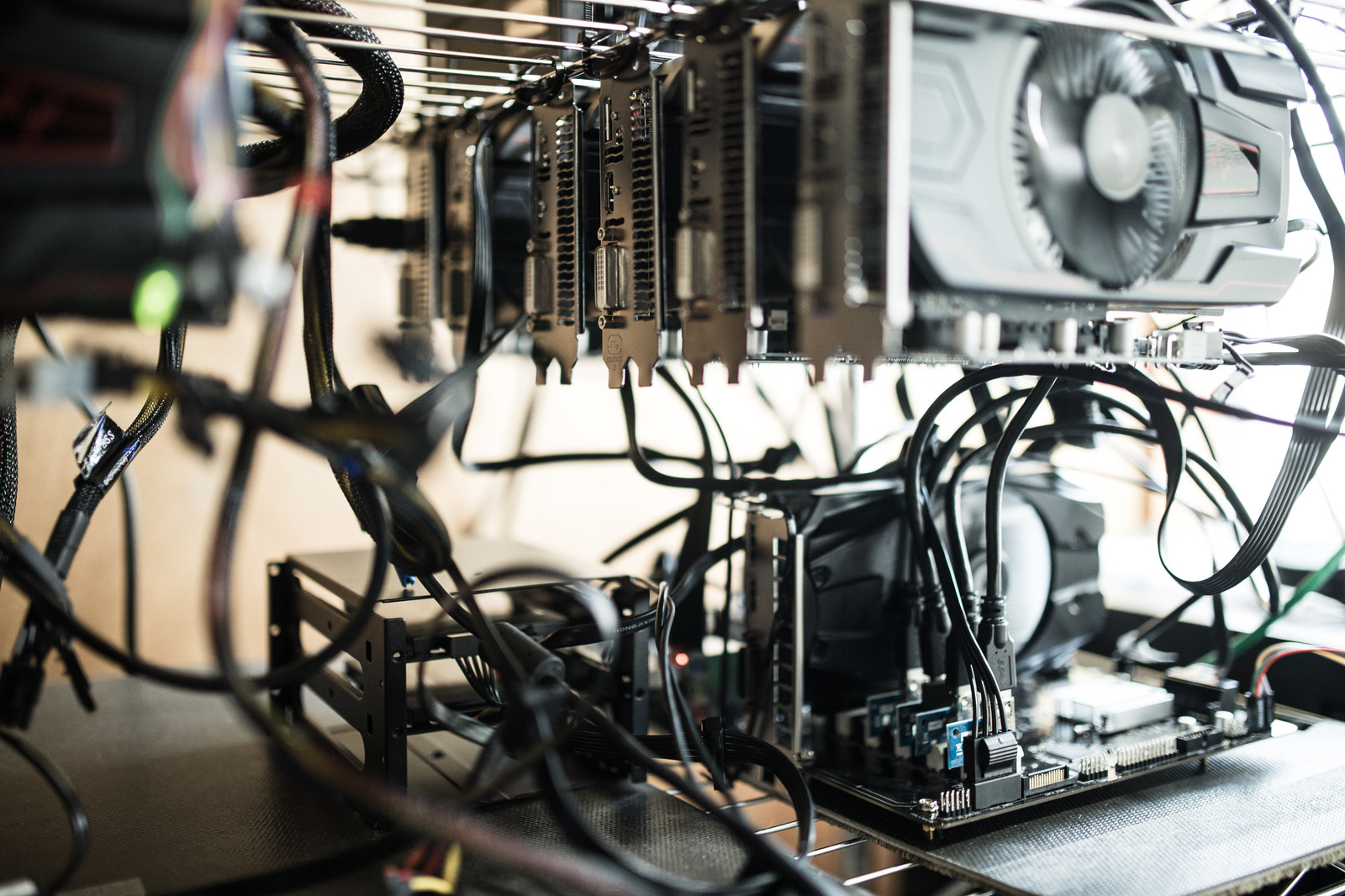

Unity application development support

Development will be done using Unity, a game development platform.

Production line safety control system

This system controls the process equipment in the production line, as well as the transfer and welding robots.

Linux device driver development support

We develop diagnostic programs to evaluate various device drivers for embedded Linux.

Cargo sorting system

The system receives the cargo data from the host by FTP communication, stores it in the DB, expands it to the sorting instruction PC, and sorts the cargo by responding quickly to the sorting destination in response to the cargo information inquiry from the equipment PLC.

Equipment sign monitoring system

Collects sensor values for pressure and power values of production equipment and stores them in a database.

Picking instruction system

This system instructs the picking of parts to be used on the assembly line by lighting picking lamps.

Solar power monitoring system

The system communicates with the power conditioners installed in the field, collects the amount of power generated, as well as failure and abnormality signals, and stores them in a database.

Temperature monitoring system using IoT

This is a system that collects temperature information centrally through the Implement of IoT of temperature measurement devices in each process to monitor and investigate product quality.

Mobile phone development support

Development based on the Android platform itself, which is available on the AOSP (Android Open Source Project)

Distant monitoring system

This is a distant monitoring system that can display the status of equipment.

Plant control and monitoring system

Plant control and monitoring system using DCS (CENTUM VP by YOKOGAWA)

Traceability system

A system that links each process from raw material input to processing to inspection with production facilities and uses a handy terminal to manage product information traceability information.

MCSimulator ~MELSEC Communication Protocol Simulator~

The main purpose of this software is to support PLC-less upper-level software development.

SMART-Touch for MELSEC PLC

This application allows you to access Mitsubishi Electric's sequencer from your Android smartphone in a wireless LAN environment and read/write device information.

Case management system

We share information by centrally managing customer and case information specialized for law firms using a database.

Precious metal management system

The system aims to improve productivity, quality, profitability, and reduce management man-hours by centrally managing the business processes in the manufacture of automotive exhaust gas filtration catalysts.

Distant monitoring system

A system that enables remote monitoring of the process status of sewage treatment facilities located in various parts of Japan by a PC at the head office.

I/O board driver development

We loaded Wind River's VxWorks real-time OS for embedded systems in a certain manufacturer's PC for FA, and developed a general-purpose driver to work with the digital/analog I/O boards made by the same manufacturer.

ALC production instruction distribution system

Production instruction data from ALC is deployed to each manufacturing process line, and quality information is stored in the database of the information management server via G/W.

Logistics and cart system

A system that integrates the management of all equipment and devices installed in a distribution center, and automates and streamlines the entire process of receiving, shipping, and inventory management of the products handled.

Film factory control system

Control system using OPTO22's SNAP Control System (automatic control of air conditioning, metering, temperature, pressure, flow, etc.)

Material handling management system

Pick up packages, inspect them with scanners, and sort them to the stores to be shipped.

High-temperature furnace temperature control system

PID control of the furnace temperature performed by PLC.

Modules for power measurement and control

A power supply control system for efficient and high-quality power supply for small-scale power systems, such as microgrids.

Simulation

The system that simulate each device and physical phenomena for OPTO22's SNAP Control System (automatic control of air conditioning, metering, temperature, pressure, flow, etc.)

Production management system

This is an integrated production management system that can manage all aspects of a factory's operations, from order receipt to production, inventory, manufacturing, and cost.

Production Instruction System

The system that pick parts based on the production instruction data from the upper level and inspect them using a handy terminal.

Product re-inspection system

System to digitize product re-inspection information (re-inspection data)

Fruit selection system (traceability)

Automatic identification of the grade and class of produce received from the producer by image processing (traceability)

Receiving and shipping management system

A receiving and shipping management system that uses a handy terminal to input results.

Medication checking system

The system is to eliminate medication errors and reduce the workload of staff by systematizing the human medication checking process (automatic checking using RFID).

Digitalization of production history information

We digitalized production history information

Power demand monitoring system

OPTO's PAC controller captures power data and stores the data in a database for a long period of time.

Equipment control monitoring system

Real-time monitoring of various production facility conditions and notification to operators.

Equipment control management

Integrated management of manufacturing execution by linking manufacturing/shipping instructions, material arrival/inspection/modification information, etc. from the upper level.

Utility integrated monitoring

Collects various process signals and analog signals from each utility facility (air conditioning, piping, electricity, water treatment, gas, chemical supply, cold and heat source, etc.) in the production plant.

Coil inspection system

The system that inputs the flaw inspection of steel sheets while winding coils.

Inspection and shipping system

Systematization of the fabric inspection and shipping processes, including inspection acceptance, inspection, packaging, shipping, and warehousing.

Biological testing system

The system that manages test using living organisms (guinea pigs, mice, etc.), from giving orders to conducting tests and creating reports.

Emergency Shake ~App to shake and inform~

This is an app that informs others of an emergency by shaking your device to send an emergency sound and notification.